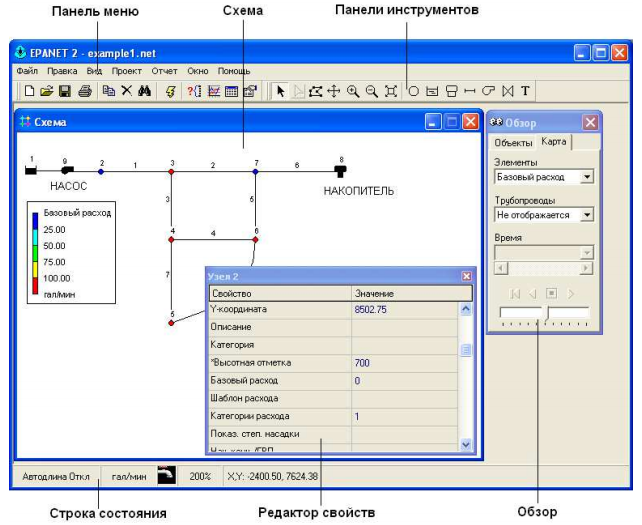

Update 24/02/2014: there is new EPANET C# class here.

Thanks to abcprogramlama (site in Turkish) I finally got the EPANet Toolkit working in C# (C-sharp). First the EpanetCSharpLibrary should be added to the solution (click to expend or download here):

[code language=”csharp” collapse=”true”]

using System;

using System.Runtime.InteropServices;

namespace EpanetCSharpLibrary

{

public static class Epanet

{

public const string EPANETDLL = "epanet2.dll";

public const int EN_ELEVATION = 0;

public const int EN_BASEDEMAND = 1;

public const int EN_PATTERN = 2;

public const int EN_EMITTER = 3;

public const int EN_INITQUAL = 4;

public const int EN_SOURCEQUAL = 5;

public const int EN_SOURCEPAT = 6;

public const int EN_SOURCETYPE = 7;

public const int EN_TANKLEVEL = 8;

public const int EN_DEMAND = 9;

public const int EN_HEAD = 10;

public const int EN_PRESSURE = 11;

public const int EN_QUALITY = 12;

public const int EN_SOURCEMASS = 13;

public const int EN_INITVOLUME = 14;

public const int EN_MIXMODEL = 15;

public const int EN_MIXZONEVOL = 16;

public const int EN_TANKDIAM = 17;

public const int EN_MINVOLUME = 18;

public const int EN_VOLCURVE = 19;

public const int EN_MINLEVEL = 20;

public const int EN_MAXLEVEL = 21;

public const int EN_MIXFRACTION = 22;

public const int EN_TANK_KBULK = 23;

public const int EN_DIAMETER = 0;

public const int EN_LENGTH = 1;

public const int EN_ROUGHNESS = 2;

public const int EN_MINORLOSS = 3;

public const int EN_INITSTATUS = 4;

public const int EN_INITSETTING = 5;

public const int EN_KBULK = 6;

public const int EN_KWALL = 7;

public const int EN_FLOW = 8;

public const int EN_VELOCITY = 9;

public const int EN_HEADLOSS = 10;

public const int EN_STATUS = 11;

public const int EN_SETTING = 12;

public const int EN_ENERGY = 13;

public const int EN_DURATION = 0;

public const int EN_HYDSTEP = 1;

public const int EN_QUALSTEP = 2;

public const int EN_PATTERNSTEP = 3;

public const int EN_PATTERNSTART = 4;

public const int EN_REPORTSTEP = 5;

public const int EN_REPORTSTART = 6;

public const int EN_RULESTEP = 7;

public const int EN_STATISTIC = 8;

public const int EN_PERIODS = 9;

public const int EN_NODECOUNT = 0;

public const int EN_TANKCOUNT = 1;

public const int EN_LINKCOUNT = 2;

public const int EN_PATCOUNT = 3;

public const int EN_CURVECOUNT = 4;

public const int EN_CONTROLCOUNT = 5;

public const int EN_JUNCTION = 0;

public const int EN_RESERVOIR = 1;

public const int EN_TANK = 2;

public const int EN_CVPIPE = 0;

public const int EN_PIPE = 1;

public const int EN_PUMP = 2;

public const int EN_PRV = 3;

public const int EN_PSV = 4;

public const int EN_PBV = 5;

public const int EN_FCV = 6;

public const int EN_TCV = 7;

public const int EN_GPV = 8;

public const int EN_NONE = 0;

public const int EN_CHEM = 1;

public const int EN_AGE = 2;

public const int EN_TRACE = 3;

public const int EN_CONCEN = 0;

public const int EN_MASS = 1;

public const int EN_SETPOINT = 2;

public const int EN_FLOWPACED = 3;

public const int EN_CFS = 0;

public const int EN_GPM = 1;

public const int EN_MGD = 2;

public const int EN_IMGD = 3;

public const int EN_AFD = 4;

public const int EN_LPS = 5;

public const int EN_LPM = 6;

public const int EN_MLD = 7;

public const int EN_CMH = 8;

public const int EN_CMD = 9;

public const int EN_TRIALS = 0;

public const int EN_ACCURACY = 1;

public const int EN_TOLERANCE = 2;

public const int EN_EMITEXPON = 3;

public const int EN_DEMANDMULT = 4;

public const int EN_LOWLEVEL = 0;

public const int EN_HILEVEL = 1;

public const int EN_TIMER = 2;

public const int EN_TIMEOFDAY = 3;

public const int EN_AVERAGE = 1;

public const int EN_MINIMUM = 2;

public const int EN_MAXIMUM = 3;

public const int EN_RANGE = 4;

public const int EN_MIX1 = 0;

public const int EN_MIX2 = 1;

public const int EN_FIFO = 2;

public const int EN_LIFO = 3;

public const int EN_NOSAVE = 0;

public const int EN_SAVE = 1;

public const int EN_INITFLOW = 10;

#region Epanet Imports

public delegate void UserSuppliedFunction(string param0);

/// <summary>

/// Runs a complete EPANET simulation.

/// </summary>

/// <param name="f1">name of the input file</param>

/// <param name="f2">name of an output report file</param>

/// <param name="f3">name of an output output file </param>

/// <param name="vfunc">pointer to a user-supplied function which accepts a character string as its argument</param>

/// <returns>Returns an error code.</returns>

[DllImport(EPANETDLL, EntryPoint = "ENepanet")]

public static extern int ENepanet(string f1, string f2, string f3, UserSuppliedFunction vfunc);

/// <summary>

/// Opens the Toolkit to analyze a particular distribution system.

/// </summary>

/// <param name="param0">name of the input file</param>

/// <param name="param1">name of an output report file</param>

/// <param name="param2">name of an output output file</param>

/// <returns>Returns an error code.</returns>

[DllImportAttribute(EPANETDLL, EntryPoint = "ENopen")]

public static extern int ENopen(string param0, string param1, string param2);

/// <summary>

/// Writes all current network input data to a file using the format of an EPANET input file.

/// </summary>

/// <param name="filename">name of the file where data is saved.</param>

/// <returns></returns>

[DllImportAttribute(EPANETDLL, EntryPoint = "ENsaveinpfile")]

public static extern int ENsaveinpfile(string filename);

/// <summary>

/// Closes down the Toolkit system (including all files being processed).

/// </summary>

/// <returns></returns>

[DllImportAttribute(EPANETDLL, EntryPoint = "ENclose")]

public static extern int ENclose();

/// <summary>

/// Runs a complete hydraulic simulation with results

/// for all time periods written to the binary Hydraulics file.

/// </summary>

/// <returns></returns>

[DllImportAttribute(EPANETDLL, EntryPoint = "ENsolveH")]

public static extern int ENsolveH();

/// <summary>

/// Transfers results of a hydraulic simulation from the binary Hydraulics file to the binary Output file,

/// where results are only reported at uniform reporting intervals.

/// </summary>

/// <returns></returns>

[DllImportAttribute(EPANETDLL, EntryPoint = "ENsaveH")]

public static extern int ENsaveH();

/// <summary>

/// Opens the hydraulics analysis system.

/// </summary>

/// <returns></returns>

[DllImportAttribute(EPANETDLL, EntryPoint = "ENopenH")]

public static extern int ENopenH();

/// <summary>

/// Initializes storage tank levels, link status and settings,

/// and the simulation clock time prior to running a hydraulic analysis.

/// </summary>

/// <param name="saveflag">0-1 flag indicating if hydraulic results will be saved to the hydraulics file.</param>

/// <returns></returns>

[DllImportAttribute(EPANETDLL, EntryPoint = "ENinitH")]

public static extern int ENinitH(int saveflag);

/// <summary>

/// Runs a single period hydraulic analysis, retrieving the current simulation clock time t.

/// </summary>

/// <param name="t">current simulation clock time in seconds.</param>

/// <returns></returns>

[DllImportAttribute(EPANETDLL, EntryPoint = "ENrunH")]

public static extern int ENrunH(ref long t);

/// <summary>

/// Determines the length of time until the next hydraulic event occurs in an extended period simulation.

/// </summary>

/// <param name="tstep">time (in seconds) until next hydraulic event occurs or

/// 0 if at the end of the simulation period.</param>

/// <returns></returns>

[DllImportAttribute(EPANETDLL, EntryPoint = "ENnextH")]

public static extern int ENnextH(ref long tstep);

/// <summary>

/// Closes the hydraulic analysis system, freeing all allocated memory.

/// </summary>

/// <returns></returns>

[DllImportAttribute(EPANETDLL, EntryPoint = "ENcloseH")]

public static extern int ENcloseH();

/// <summary>

/// Saves the current contents of the binary hydraulics file to a file.

/// </summary>

/// <param name="fname">name of the file where the hydraulics results should be saved.</param>

/// <returns></returns>

[DllImportAttribute(EPANETDLL, EntryPoint = "ENsavehydfile")]

public static extern int ENsavehydfile(string fname);

/// <summary>

/// Uses the contents of the specified file as the current binary hydraulics file.

/// </summary>

/// <param name="fname">name of the file containing hydraulic analysis results for the current network.</param>

/// <returns></returns>

[DllImportAttribute(EPANETDLL, EntryPoint = "ENusehydfile")]

public static extern int ENusehydfile(string fname);

/// <summary>

/// Runs a complete water quality simulation with results at uniform reporting

/// intervals written to EPANET’s binary Output file.

/// </summary>

/// <returns></returns>

[DllImportAttribute(EPANETDLL, EntryPoint = "ENsolveQ")]

public static extern int ENsolveQ();

/// <summary>

/// Opens the water quality analysis system.

/// </summary>

/// <returns></returns>

[DllImportAttribute(EPANETDLL, EntryPoint = "ENopenQ")]

public static extern int ENopenQ();

/// <summary>

/// Initializes water quality and the simulation clock time prior to running a water quality analysis.

/// </summary>

/// <param name="saveflag">0-1 flag indicating if analysis results

/// should be saved to EPANET’s binary output file at uniform reporting periods.</param>

/// <returns></returns>

[DllImportAttribute(EPANETDLL, EntryPoint = " ENinitQ")]

public static extern int ENinitQ(int saveflag);

/// <summary>

/// Makes available the hydraulic and water quality results that occur

/// at the start of the next time period of a water quality analysis,

/// where the start of the period is returned in t.

/// </summary>

/// <param name="t">current simulation clock time in seconds.</param>

/// <returns></returns>

[DllImportAttribute(EPANETDLL, EntryPoint = "ENrunQ")]

public static extern int ENrunQ(ref long t);

/// <summary>

/// Advances the water quality simulation to the start of the next hydraulic time period.

/// </summary>

/// <param name="tstep">time (in seconds) until next hydraulic event occurs or

/// 0 if at the end of the simulation period.</param>

/// <returns></returns>

[DllImportAttribute(EPANETDLL, EntryPoint = "ENnextQ")]

public static extern int ENnextQ(ref long tstep);

/// <summary>

/// Advances the water quality simulation one water quality time step.

/// The time remaining in the overall simulation is returned in tleft.

/// </summary>

/// <param name="tleft">seconds remaining in the overall simulation duration.</param>

/// <returns></returns>

[DllImportAttribute(EPANETDLL, EntryPoint = "ENstepQ")]

public static extern int ENstepQ(ref long tleft);

/// <summary>

/// Closes the water quality analysis system, freeing all allocated memory.

/// </summary>

/// <returns></returns>

[DllImportAttribute(EPANETDLL, EntryPoint = "ENcloseQ")]

public static extern int ENcloseQ();

/// <summary>

/// Writes a line of text to the EPANET report file.

/// </summary>

/// <param name="line">text to be written to file.</param>

/// <returns></returns>

[DllImportAttribute(EPANETDLL, EntryPoint = "ENwriteline")]

public static extern int ENwriteline(string line);

/// <summary>

/// Writes a formatted text report on simulation results to the Report file.

/// </summary>

/// <returns></returns>

[DllImportAttribute(EPANETDLL, EntryPoint = "ENreport")]

public static extern int ENreport();

/// <summary>

/// Clears any report formatting commands that either appeared in the

/// [REPORT] section of the EPANET Input file or were issued with the ENsetreport function.

/// </summary>

/// <returns></returns>

[DllImportAttribute(EPANETDLL, EntryPoint = "ENresetreport")]

public static extern int ENresetreport();

/// <summary>

/// Issues a report formatting command.

/// Formatting commands are the same as used in the

/// [REPORT] section of the EPANET Input file.

/// </summary>

/// <param name="command">text of a report formatting command.</param>

/// <returns></returns>

[DllImportAttribute(EPANETDLL, EntryPoint = "ENsetreport")]

public static extern int ENsetreport(string command);

/// <summary>

/// Retrieves the parameters of a simple control statement.

/// The index of the control is specified in cindex and

/// the remaining arguments return the control’s parameters.

/// </summary>

/// <param name="cindex">control statement index</param>

/// <param name="ctype">control type code</param>

/// <param name="lindex">index of link being controlled</param>

/// <param name="setting">value of the control setting</param>

/// <param name="nindex">index of controlling node</param>

/// <param name="level">value of controlling water level or

/// pressure for level controls or of time of control action (in seconds)

/// for time-based controls</param>

/// <returns></returns>

[DllImportAttribute(EPANETDLL, EntryPoint = "ENgetcontrol")]

public static extern int ENgetcontrol(int cindex, ref int ctype, ref int lindex,

ref float setting, ref int nindex, ref float level);

/// <summary>

/// Retrieves the number of network components of a specified type.

/// </summary>

/// <param name="countcode">component code</param>

/// <param name="count">number of countcode components in the network</param>

/// <returns></returns>

[DllImportAttribute(EPANETDLL, EntryPoint = "ENgetcount")]

public static extern int ENgetcount(int countcode, ref int count);

/// <summary>

/// Retrieves the value of a particular analysis option.

/// </summary>

/// <param name="optioncode">an option code</param>

/// <param name="value">an option value</param>

/// <returns></returns>

[DllImportAttribute(EPANETDLL, EntryPoint = "ENgetoption")]

public static extern int ENgetoption(int optioncode, ref float value);

/// <summary>

/// Retrieves the value of a specific analysis time parameter.

/// </summary>

/// <param name="paramcode">time parameter code</param>

/// <param name="timevalue">value of time parameter in seconds</param>

/// <returns></returns>

[DllImportAttribute(EPANETDLL, EntryPoint = "ENgettimeparam")]

public static extern int ENgettimeparam(int paramcode, ref int timevalue);

/// <summary>

/// Retrieves a code number indicating the units used to express all flow rates.

/// </summary>

/// <param name="unitscode">value of a flow units code number</param>

/// <returns></returns>

[DllImportAttribute(EPANETDLL, EntryPoint = "ENgetflowunits")]

public static extern int ENgetflowunits(ref int unitscode);

/// <summary>

/// Retrieves the index of a particular time pattern.

/// </summary>

/// <param name="id">pattern ID label</param>

/// <param name="index">pattern index</param>

/// <returns></returns>

[DllImportAttribute(EPANETDLL, EntryPoint = "ENgetpatternindex")]

public static extern int ENgetpatternindex(string id, ref int index);

/// <summary>

/// Retrieves the ID label of a particular time pattern.

/// </summary>

/// <param name="index">pattern index</param>

/// <param name="id">ID label of pattern</param>

/// <returns></returns>

[DllImportAttribute(EPANETDLL, EntryPoint = "ENgetpatternid")]

public static extern int ENgetpatternid(int index, string id);

/// <summary>

/// Retrieves the number of time periods in a specific time pattern.

/// </summary>

/// <param name="index">pattern index</param>

/// <param name="len">number of time periods in the pattern</param>

/// <returns></returns>

[DllImportAttribute(EPANETDLL, EntryPoint = "ENgetpatternlen")]

public static extern int ENgetpatternlen(int index, ref int len);

/// <summary>

/// Retrieves the multiplier factor for a specific time period in a time pattern.

/// </summary>

/// <param name="index">time pattern index</param>

/// <param name="period">period within time pattern</param>

/// <param name="value">multiplier factor for the period</param>

/// <returns></returns>

[DllImportAttribute(EPANETDLL, EntryPoint = "ENgetpatternvalue")]

public static extern int ENgetpatternvalue(int index, int period, ref float value);

/// <summary>

/// Retrieves the type of water quality analysis called for.

/// </summary>

/// <param name="qualcode">water quality analysis code</param>

/// <param name="tracenode">index of node traced in a source tracing analysis</param>

/// <returns></returns>

[DllImportAttribute(EPANETDLL, EntryPoint = "ENgetqualtype")]

public static extern int ENgetqualtype(ref int qualcode, ref int tracenode);

/// <summary>

/// Retrieves the text of the message associated with a particular error or warning code.

/// </summary>

/// <param name="errcode">error or warning code</param>

/// <param name="errmsg">text of the error or warning message for errcode</param>

/// <param name="nchar">maximum number of characters that errmsg can hold</param>

/// <returns></returns>

[DllImportAttribute(EPANETDLL, EntryPoint = "ENgeterror")]

public static extern int ENgeterror(int errcode, string errmsg, int nchar);

/// <summary>

/// Retrieves the index of a node with a specified ID.

/// </summary>

/// <param name="id">node ID label</param>

/// <param name="index">node index</param>

/// <returns></returns>

[DllImportAttribute(EPANETDLL, EntryPoint = "ENgetnodeindex")]

public static extern int ENgetnodeindex(string id, ref int index);

/// <summary>

/// Retrieves the ID label of a node with a specified index

/// </summary>

/// <param name="index">node index</param>

/// <param name="id">ID label of node</param>

/// <returns></returns>

[DllImportAttribute(EPANETDLL, EntryPoint = "ENgetnodeid")]

public static extern int ENgetnodeid(int index, string id);

/// <summary>

/// Retrieves the node-type code for a specific node.

/// </summary>

/// <param name="index">node index</param>

/// <param name="typecode">node-type code</param>

/// <returns></returns>

[DllImportAttribute(EPANETDLL, EntryPoint = "ENgetnodetype")]

public static extern int ENgetnodetype(int index, ref int typecode);

/// <summary>

/// Retrieves the value of a specific link parameter.

/// </summary>

/// <param name="index">node index</param>

/// <param name="paramcode">parameter code</param>

/// <param name="value">parameter value</param>

/// <returns></returns>

[DllImportAttribute(EPANETDLL, EntryPoint = "ENgetnodevalue")]

public static extern int ENgetnodevalue(int index, int paramcode, ref float value);

/// <summary>

/// Retrieves the index of a link with a specified ID.

/// </summary>

/// <param name="id">link ID label</param>

/// <param name="index">link index</param>

/// <returns></returns>

[DllImportAttribute(EPANETDLL, EntryPoint = "ENgetlinkindex")]

public static extern int ENgetlinkindex(string id, ref int index);

/// <summary>

/// Retrieves the ID label of a link with a specified index.

/// </summary>

/// <param name="index">link index</param>

/// <param name="id">ID label of link</param>

/// <returns></returns>

[DllImportAttribute(EPANETDLL, EntryPoint = "ENgetlinkid")]

public static extern int ENgetlinkid(int index, string id);

/// <summary>

/// Retrieves the link-type code for a specific link.

/// </summary>

/// <param name="index">link index</param>

/// <param name="typecode">link-type code</param>

/// <returns></returns>

[DllImportAttribute(EPANETDLL, EntryPoint = "ENgetlinktype")]

public static extern int ENgetlinktype(int index, ref int typecode);

/// <summary>

/// Retrieves the indexes of the end nodes of a specified link.

/// </summary>

/// <param name="index">link index</param>

/// <param name="fromnode">index of node at start of link</param>

/// <param name="tonode">index of node at end of link</param>

/// <returns></returns>

[DllImportAttribute(EPANETDLL, EntryPoint = "ENgetlinknodes")]

public static extern int ENgetlinknodes(int index, ref int fromnode, ref int tonode);

/// <summary>

/// Retrieves the value of a specific link parameter.

/// </summary>

/// <param name="index">link index</param>

/// <param name="paramcode">parameter code</param>

/// <param name="value">parameter value</param>

/// <returns></returns>

[DllImportAttribute(EPANETDLL, EntryPoint = "ENgetlinkvalue")]

public static extern int ENgetlinkvalue(int index, int paramcode, ref float value);

/// <summary>

/// Retrieves version.

/// </summary>

/// <param name="version">Version</param>

/// <returns></returns>

[DllImportAttribute(EPANETDLL, EntryPoint = "ENgetversion")]

public static extern int ENgetversion(ref int version);

/// <summary>

/// Sets the parameters of a simple control statement.

/// </summary>

/// <param name="cindex">control statement index</param>

/// <param name="ctype">control type code</param>

/// <param name="lindex">index of link being controlled</param>

/// <param name="setting">value of the control setting</param>

/// <param name="nindex">index of controlling node</param>

/// <param name="level">value of controlling water level or pressure

/// for level controls or of time of control action (in seconds)

/// for time-based controls</param>

/// <returns></returns>

[DllImportAttribute(EPANETDLL, EntryPoint = "ENsetcontrol")]

public static extern int ENsetcontrol(int cindex, int ctype, int lindex,

float setting, int nindex, float level);

/// <summary>

/// Sets the value of a parameter for a specific node.

/// </summary>

/// <param name="index">node index</param>

/// <param name="paramcode">parameter code</param>

/// <param name="value">parameter value</param>

/// <returns></returns>

[DllImportAttribute(EPANETDLL, EntryPoint = "ENsetnodevalue")]

public static extern int ENsetnodevalue(int index, int paramcode, float value);

/// <summary>

/// Sets the value of a parameter for a specific link.

/// </summary>

/// <param name="index">link index</param>

/// <param name="paramcode">parameter code</param>

/// <param name="value">parameter value</param>

/// <returns></returns>

[DllImportAttribute(EPANETDLL, EntryPoint = "ENsetlinkvalue")]

public static extern int ENsetlinkvalue(int index, int paramcode, float value);

/// <summary>

/// Adds a new time pattern to the network.

/// </summary>

/// <param name="id">ID label of pattern</param>

/// <returns></returns>

[DllImportAttribute(EPANETDLL, EntryPoint = "ENaddpattern")]

public static extern int ENaddpattern(string id);

/// <summary>

/// Sets all of the multiplier factors for a specific time pattern.

/// </summary>

/// <param name="index">time pattern index</param>

/// <param name="factors">multiplier factors for the entire pattern</param>

/// <param name="nfactors">number of factors in the pattern</param>

/// <returns></returns>

[DllImportAttribute(EPANETDLL, EntryPoint = "ENsetpattern")]

public static extern int ENsetpattern(int index, float[] factors, int nfactors);

/// <summary>

/// Sets the multiplier factor for a specific period within a time pattern.

/// </summary>

/// <param name="index">time pattern index</param>

/// <param name="period">period within time pattern</param>

/// <param name="value">multiplier factor for the period</param>

/// <returns></returns>

[DllImportAttribute(EPANETDLL, EntryPoint = "ENsetpatternvalue")]

public static extern int ENsetpatternvalue(int index, int period, float value);

/// <summary>

/// Sets the value of a time parameter.

/// </summary>

/// <param name="paramcode">time parameter code</param>

/// <param name="timevalue">value of time parameter in seconds</param>

/// <returns></returns>

[DllImportAttribute(EPANETDLL, EntryPoint = "ENsettimeparam")]

public static extern int ENsettimeparam(int paramcode, long timevalue);

/// <summary>

/// Sets the value of a particular analysis option.

/// </summary>

/// <param name="optioncode">an option code</param>

/// <param name="value">an option value</param>

/// <returns></returns>

[DllImportAttribute(EPANETDLL, EntryPoint = "ENsetoption")]

public static extern int ENsetoption(int optioncode, float value);

/// <summary>

/// Sets the level of hydraulic status reporting.

/// </summary>

/// <param name="statuslevel">level of status reporting</param>

/// <returns></returns>

[DllImportAttribute(EPANETDLL, EntryPoint = "ENsetstatusreport")]

public static extern int ENsetstatusreport(int statuslevel);

/// <summary>

/// Sets the type of water quality analysis called for.

/// </summary>

/// <param name="qualcode">water quality analysis code</param>

/// <param name="chemname">name of the chemical being analyzed</param>

/// <param name="chemunits">units that the chemical is measured in</param>

/// <param name="tracenode">ID of node traced in a source tracing analysis</param>

/// <returns></returns>

[DllImportAttribute(EPANETDLL, EntryPoint = "ENsetqualtype")]

public static extern int ENsetqualtype(int qualcode, string chemname, string chemunits, string tracenode);

#endregion

}

}

[/code]

Now the EPANet class can be used:

[code language=”csharp” collapse=”false”]

public static void Main()

{

int i = 0;

int v = 0;

string f1="", f2="", f3="";

//get the DLL’s version

i = Epanet.ENgetversion(ref v);

f1 = "Net1.inp";

f2 = "out.txt";

f3 = "rep.txt";

//run an EPANet simulation

i = Epanet.ENepanet(f1, f2, f3, null);

}

[/code]

Turns out to be simple…